From its new headquarters in Hamilton’s Burbush suburb, the team of 65+ has spent more than 40 years solving complex production automation challenges for some of the world’s biggest brands including Fonterra, Nestlé and Mars alongside local brands like Talley’s and Tatua.

Now, with a purpose-built facility and a sharper global focus, this tech-driven company is bringing world-class innovation into view and making the case for smarter, human-centered automation at scale.

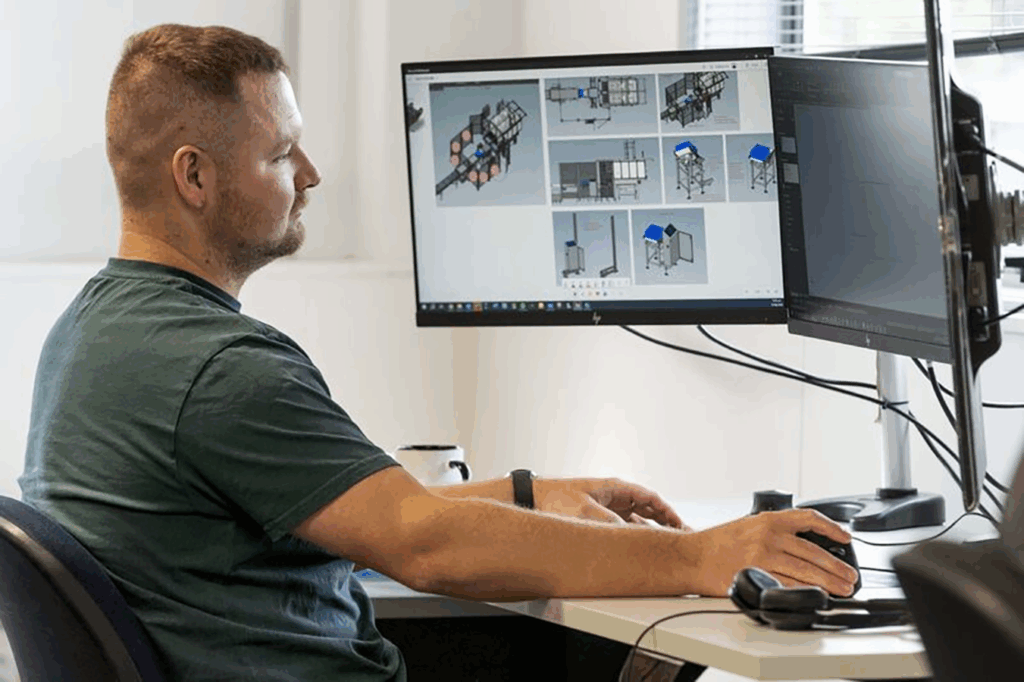

First sketch to final test

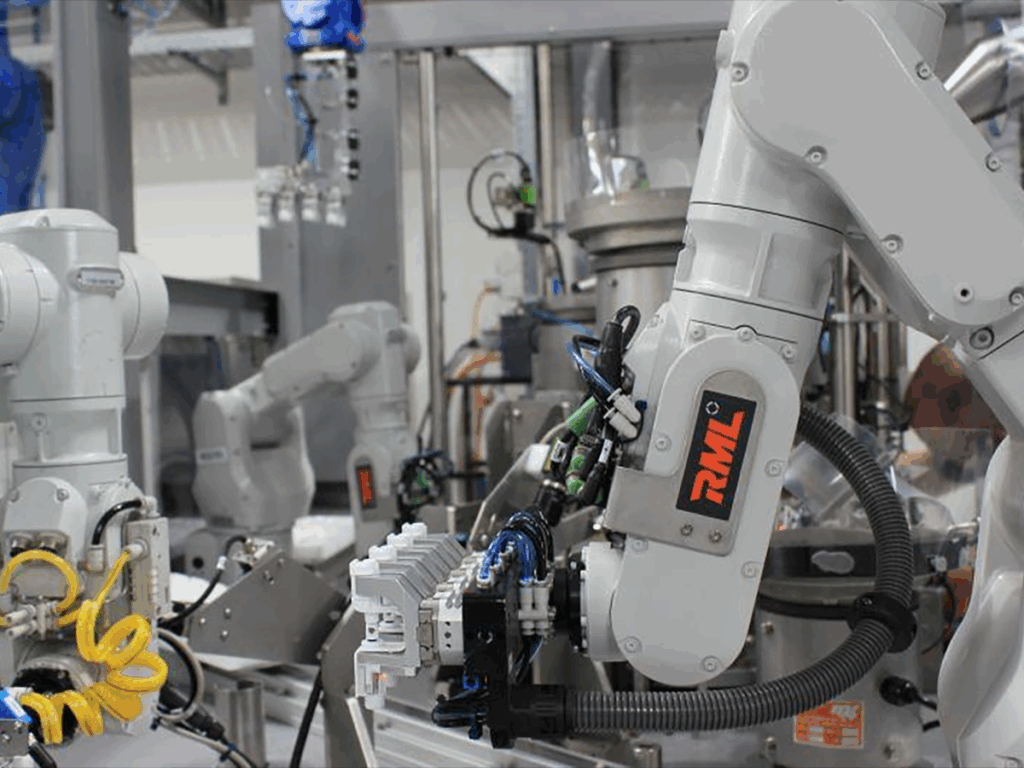

With automated guided vehicles, robotics and high-speed packing lines, RML machines provide some of the most sophisticated solutions on the market for the FMCG, dairy and logistics sectors.

As CEO, Daryl Joyce explains, everything RML builds is designed to take complexity out of manufacturing and unlock productivity.

“Our goal is to eliminate repetitive, low-value tasks and give great people the opportunity to focus on work that’s engaging and meaningful.”

The company’s end-to-end service model means the whole lot – from concept design to engineering, manufacturing and lifetime support – happens in-house, which is something customers are increasingly asking for.

According to Daryl, it’s this integrated approach that allows them to move and adapt quickly and deliver solutions that are both dynamic and globally competitive.

“Most customers come to us with a specific, unique challenge and while we often start with proven components, we adapt and engineer them to fit their specific needs,” says Daryl.

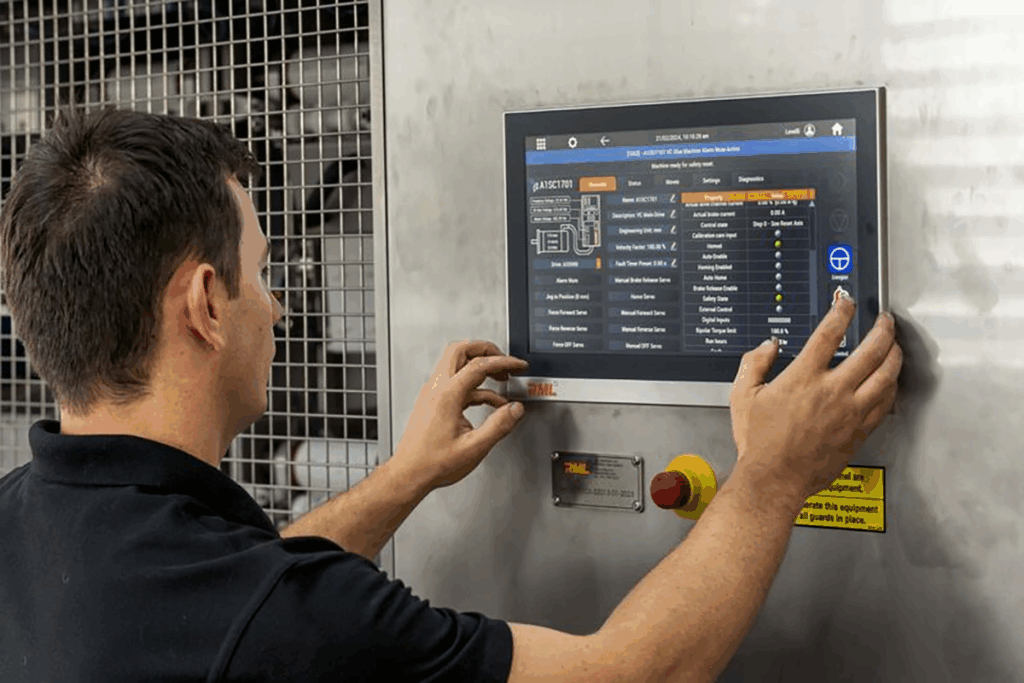

And the support doesn’t end once a machine leaves the workshop.

RML Machinery continues to monitor many systems remotely via CCTV, with smart notifications built in to detect issues before they escalate.

“In some cases, we know if something’s not meeting performance before the customer does…we’re building platforms around that visibility so instead of reacting to production issues, we can help prevent them.”

Built to scale

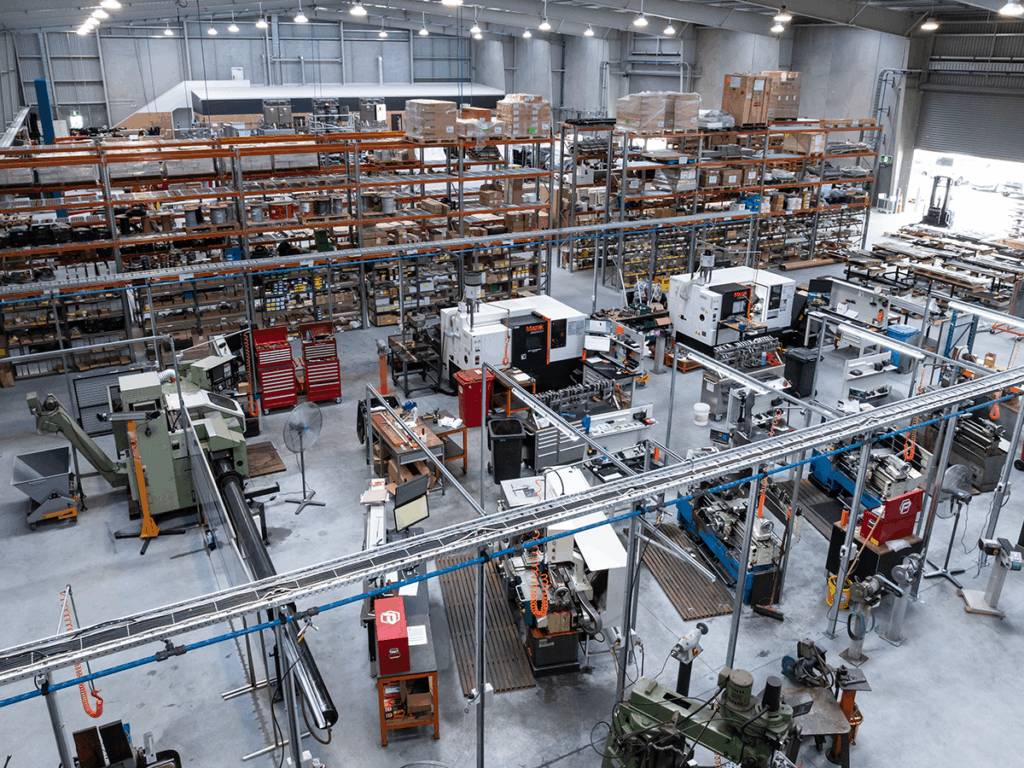

RML Machinery’s new award-winning facility, delivered in partnership with Chalmers Properties and Fosters, marks more than a physical upgrade.

Opened in October 2024, the 5,400m² purpose-built site in Te Rapa has given the company room to grow, reorganise and finally reflect the scale and sophistication of the work happening inside.

“We knew we’d outgrown the old place years ago,” says Daryl. “It was functional, but it didn’t reflect who we were or where we were going. Now, for the first time, people can walk in and immediately understand what we do and the scale we do it at.”

The new facility brings design, engineering and manufacturing teams together under one roof, improving collaboration and accelerating turnaround. It also houses the company’s service parts warehouse, allowing for faster after-sales support and raw material storage.

“We haven’t always been great at telling our story. This building helps us do that. It shows we’re serious, that we’re growing and that we’re ready for what’s next,” says Daryl.

Why Hamilton works

According to Daryl, RML Machinery’s roots in Hamilton have allowed them to build a long-standing, trusted and highly responsive local supply network. This ecosystem of support, he says, would be hard to replicate elsewhere.

“In any other part of New Zealand, I think we would struggle,” he says. “You can’t easily rebuild those mature, capable supplier relationships and we’d lose the speed and reliability they give us.”

He also believes having some of the benefits of Auckland close by, but not dealing with its operational constraints, has helped.

“In Hamilton, materials and parts can be moved quickly and collaboration happens face to face,” he says.

Plus, he says, Hamilton’s liveability has made it easier to attract and retain skilled people.

“We’ve got people coming in from Te Kauwhata, Pirongia, even Waihi Beach. It means they can build the lifestyle they want, including the kind of work they want to do.”

What’s next for RML?

With a new Hamilton facility up and running and strong ongoing demand from long-term clients, RML Machinery is now turning its focus to growth across the Tasman.

After delivering automation solutions into Australia for 20+ years, the team is now formalising its efforts and presence starting in Victoria, where the sector similarities to Waikato’s dairy and food production industries make it a natural fit.

“We’ve always had customers in Australia, but this facility gives us the confidence to build from it to attract great people, show up more visibly and grow in a focused way,” says Daryl.

As they grow overseas, production will remain in Hamilton – a deliberate choice that reflects the strength of the company’s local capability and the value of the network they’ve built around it, explains Daryl.

“The strength of our ecosystem here, which includes quality suppliers, clients and talent, as well as easy access to Auckland, is critical for our performance. It gives us a huge advantage and that’s why Hamilton will always be our base.

“We’re fortunate to have a university producing high-quality graduates, strong local schools and returning grads choosing to build their careers here. That local talent is key to how we’ll keep evolving and developing for the future.”

But for Daryl, growth is about more than market expansion. He sees industrial automation as a critical lever for improving productivity in New Zealand as a whole and helping other businesses and regions succeed.

“What really excites me is that opportunity,” he says. “How can we, as a business, help other businesses truly succeed?

“If we can improve productivity while making room for more meaningful work, that benefits everyone.”

Words by Hannah McCreery